Unlike Delta T Systems’ traditional hot oil units, this custom piece of equipment is designed to control the temperature of prototype coolant products by heating them and then cooling them in order to characterize their performance under different conditions.

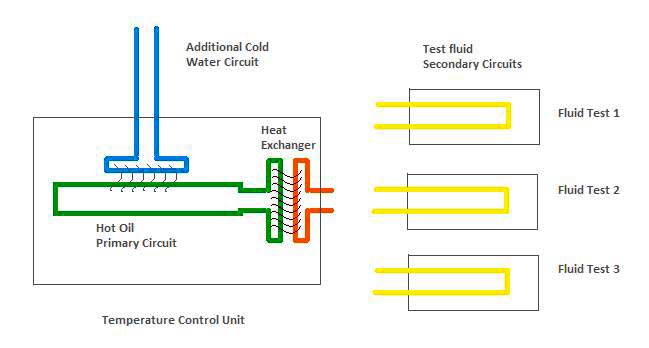

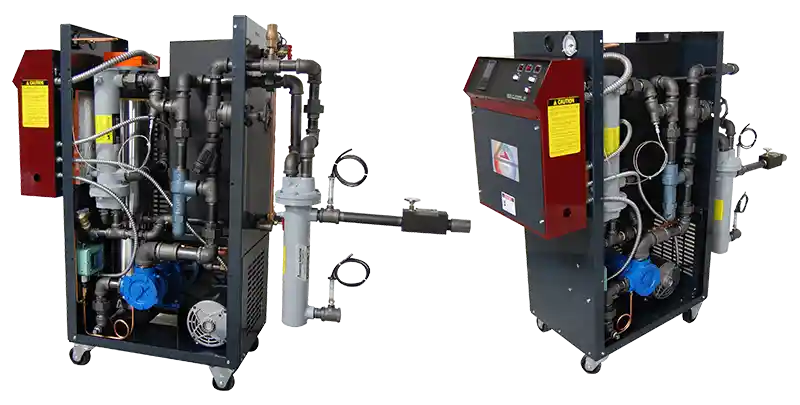

To accomplish this, Delta T has developed a custom dual circuit hot oil unit. This special design allows fluid in the controller’s primary circuit to heat or cool the process fluid in a secondary circuit; but it eliminates the possibility of cross contamination between the oil control medium and the highly corrosive process fluids under test. The temperature control system includes a flow meter, as well as pressure reading outputs for the test liquid process delivery and return ports.

Additionally, the heat exchanger between the two liquid circuits has been implemented as an external unit which allows for easy connection and disconnection to multiple secondary test fluid circuits. Various cooling fluid samples can easily be tested using the same temperature control unit.

As this particular R&D process requires not only the usual heating capability provided by oil units, but cooling as well, this Delta T Systems custom hot oil unit also includes an additional internal shell and tube heat exchanger that can be connected to an external water supply.

Whatever your process requires, count on Delta T Systems for precise temperature control.