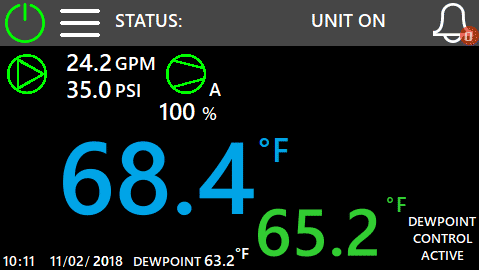

Industrial processes that require chillers for thermal management can now incorporate ambient dew point data as a process control variable. Delta T Systems’ new variable speed chiller control system is designed to monitor a production area’s ambient dew point; if a dew point increases above the process control temperature, the controller automatically adjusts the process setpoint to track with the dew point. Similarly, if the dew point decreases in a production area, the controller setpoint is adjusted downward – which often allows an increase in production rates. With this industry leading sensing capability, Delta T Systems is the only process chiller manufacturer to control all aspects of water cooled applications.

The major benefit of automated dew point/setpoint process control is condensation prevention. When process temperature is kept above an ambient dew point, no condensation occurs. Conversely, when it is below, potentially damaging condensation can occur. By preventing condensation, Delta T Systems proprietary controller will help decrease production equipment and subsystem damage or catastrophic failure.

Automatic process dew point/setpoint tracking and adjustment also decreases scrap rates, increases the strength and appearance of polymer based products and helps protect optical surfaces in lasers. It can also help eliminate unsanitary conditions in food and pharmaceutical products. All of these issues can result from water condensation coming into contact with parts or process based products such as food or pharmaceutical products.

By efficiently managing all relevant criteria in a thermal control process, Delta T Systems new variable speed chillers offer protection against condensation in the following production environments:

- Automotive

- Blow Molding

- Chemical Processing

- Chill Rolls in the Printing Industry

- Cleanrooms

- Converting

- Cosmetics

- Die Casting

- Distillation

- Electronics

- Fermentation

- Food Processing

- Injection Molding

- Pet Food Processing

- Pharmaceutical Processing

- Plastic Molding

- Pulp and Paper Processing

- Rubber Processing

Based on years of experience, Delta T Systems has designed industry leading variable speed chillers that feature superior mechanical components, controls, functionality and ease-of-use.

To learn more about Delta T Systems variable speed chiller and their applications in your industry, contact us today and speak to a knowledgeable sales representative.