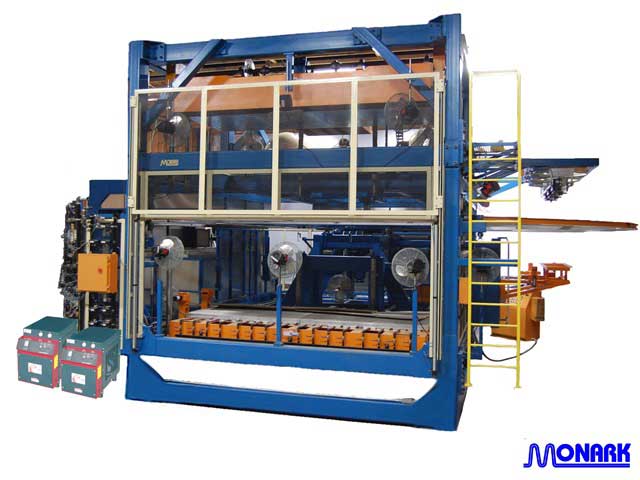

Delta T Systems recently partnered with Monark Equipment Technologies Co. to offer fully-integrated thermoforming equipment for the plastics industry. Monark rebuilds, upgrades and retro-fits more thermoforming equipment and trim presses than any other company in the USA. Like Delta T, Monark is a well-established, American-owned company that prides itself on first-class support and reliable, high quality products. Delta T Systems’ hot oil and water circulating thermolators enable Monark to offer its thermoforming equipment customers and efficient solution to their heat transfer needs.

Delta T Systems’ temperature control units are used to control the temperature of dies and molds during the thermoforming process. Thermoforming is a manufacturing process where plastic sheets are heated to a pliable temperature. The heated plastic is then inserted between two parts of a mold which are then pressed together to form a finished product. Sometimes, a vacuum is used to help the forming process, when parts have greater depth or more complex shapes. This is known as vacuum thermoforming. Thermoforming is used to manufacture items, big and small. From disposable cups to vehicle dash panels, thermoforming is a widely used plastic production process. Thermoforming is known for its low tooling costs, making it ideal for prototype development and low and medium accuracy part production.

For a variety of industrial processes where heating and cooling are needed, Delta T Systems is the ‘True Measure of Temperature Control’.

Contact us today to find out how we can solve your temperature control challenges.